These five battery technologies could be poised to challenge lithium-ion in EVs. Let’s touch upon their workings, advantages, and drawbacks to see if they could shape a sustainable future for electric mobility.

Share Post

These five battery technologies could be poised to challenge lithium-ion in EVs. Let’s touch upon their workings, advantages, and drawbacks to see if they could shape a sustainable future for electric mobility.

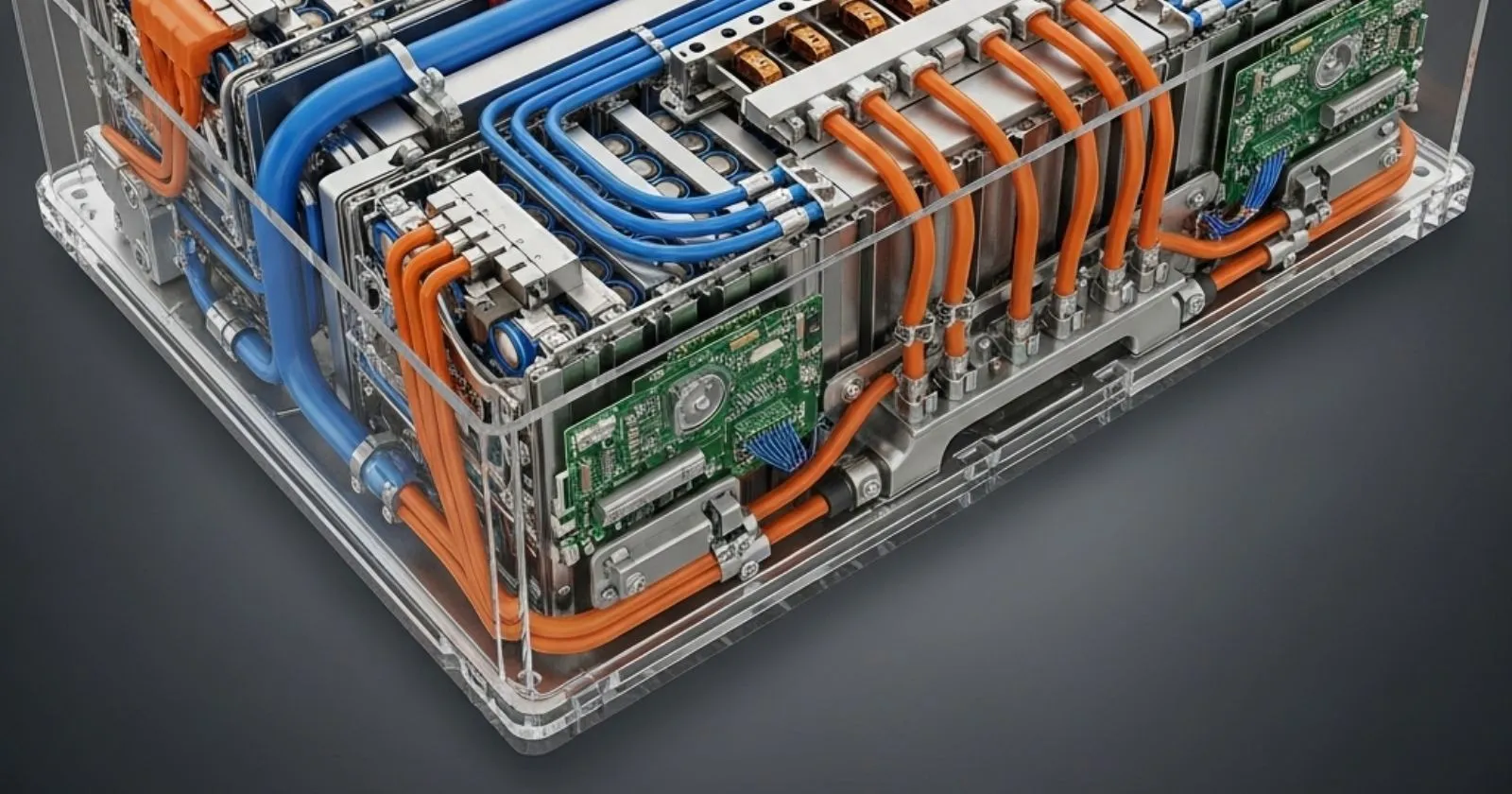

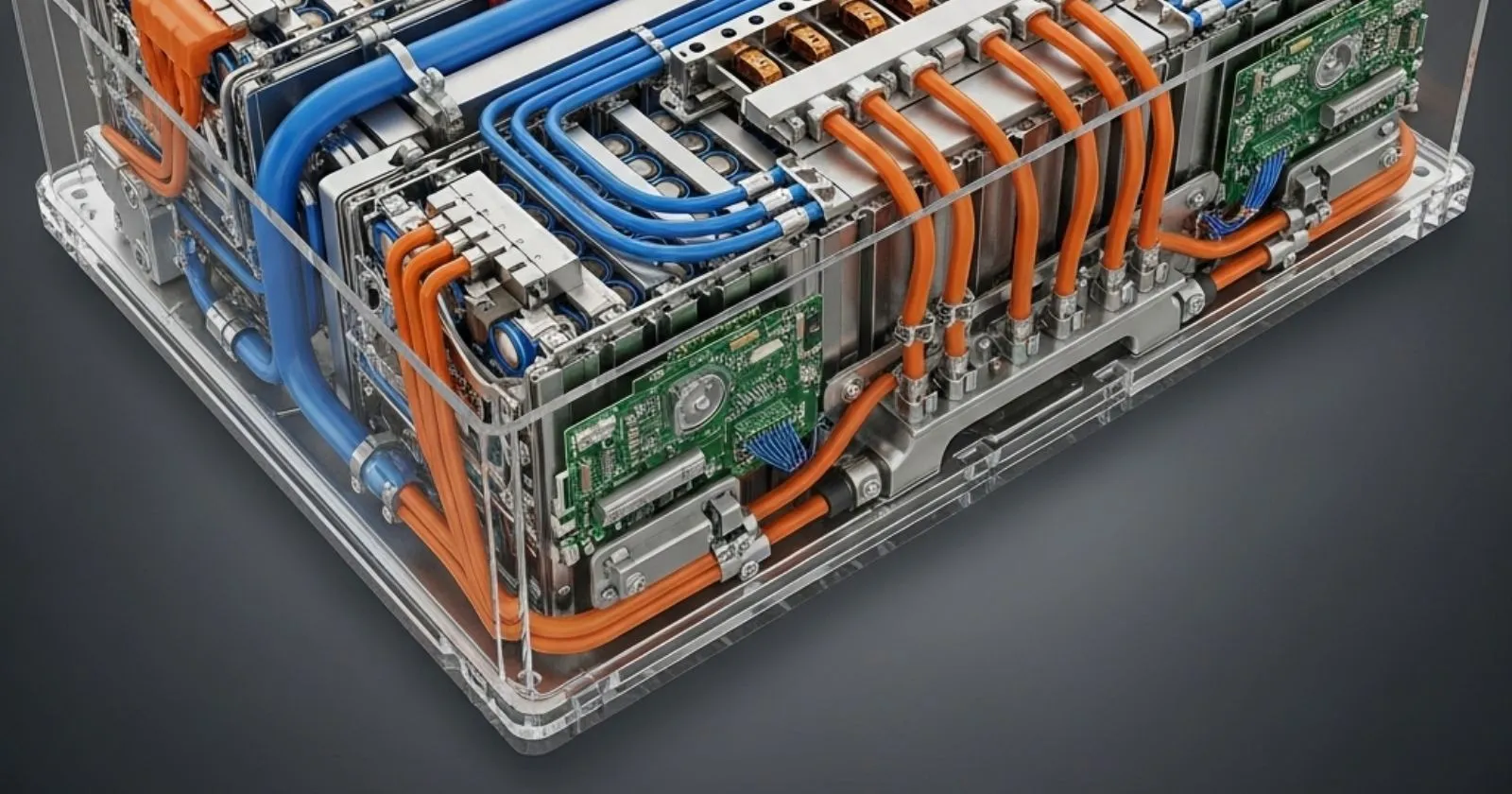

The rise of electric vehicles (EVs) is undeniable. Although a complete shift away from internal combustion engine cars remains a subject of considerable debate, there's no question that EVs are increasingly becoming a common and accepted part of our culture.

However, the backbone of most EVs, lithium-ion batteries (LIBs), has quite a few drawbacks. These include limited lithium resources, safety concerns like thermal runaway, and the environmental toll of mining cobalt and lithium.

As a result, researchers, suppliers, and carmakers are investigating alternative battery technologies to power the next generation of EVs. From sodium-ion to solid-state and vanadium redox flow to aluminium-air batteries, these alternatives aim to address cost, safety, and sustainability challenges.

So, let’s explore five of these emerging technologies, their working principles, their advantages and disadvantages compared to lithium-ion batteries, and their adoption by carmakers.

How They Work

Let’s start with a derivative of the popular lithium-ion battery. Cobalt-free lithium-ion batteries, such as those using lithium-iron-phosphate (LFP) or organic cathodes, operate like standard LIBs.

Lithium ions move between the anode and cathode via a liquid electrolyte, but the cathode avoids cobalt, and instead, uses more sustainable materials.

Advantages Over Lithium-Ion

By eliminating cobalt, these batteries address environmental and ethical concerns tied to cobalt mining.

They are cheaper to produce and, in the case of LFP batteries, offer greater stability and lower thermal runaway risks. LFP batteries also have a longer cycle life than cobalt-based LIBs.

Disadvantages Compared to Lithium-Ion

Cobalt-free LIBs, particularly LFP variants, have lower energy density (~120–160 Wh/kg) than cobalt-based LIBs, resulting in shorter ranges. They may also have slightly lower power output, affecting performance in high-demand applications.

These batteries do not address the problem of lithium shortage, in fact, there’s a projected lithium shortfall by 2035. Then, of course, there’s also the issue of limited lithium mining outside of China.

Carmakers Adopting Cobalt-Free Lithium-Ion Batteries

Tesla has adopted LFP batteries in models like the Model 3, leveraging their cost and safety benefits.

Chinese company BYD is a leader in LFP technology, and uses these batteries in vehicles like the Dolphin and Han. Lamborghini has licensed MIT’s organic cathode technology for future EVs as well.

How They Work

Sodium-ion batteries (SIBs) function similarly to lithium-ion batteries but use sodium ions (Na⁺) instead of lithium ions (Li⁺) as charge carriers. The battery comprises a cathode (often sodium cobaltate or Prussian blue analogues), an anode (typically hard carbon), and an electrolyte (organic solvents or aqueous solutions).

During charging, sodium ions move from the cathode to the anode through the electrolyte, storing energy. During discharge, the ions return to the cathode, generating electricity to power the vehicle.

Advantages Over Lithium-Ion

Sodium-ion batteries offer several compelling benefits. Sodium is abundant, found in seawater and salt deposits, making SIBs significantly cheaper than LIBs, which rely on scarce and expensive lithium.

Additionally, SIBs avoid cobalt and nickel, reducing the environmental and ethical concerns associated with mining these materials. They are also safer, with higher electrolyte flashpoints that lower flammability risks.

SIBs can be discharged to zero volts for safe storage and transport, unlike LIBs, which require careful handling. Furthermore, existing lithium-ion production lines can be adapted for SIB manufacturing, facilitating scalability.

Disadvantages Compared to Lithium-Ion

Despite their promise, SIBs have limitations. Their energy density (140–160 Wh/kg) is lower than that of LIBs (150–260 Wh/kg), resulting in shorter driving ranges for EVs.

Current SIBs also have a shorter cycle life (around 5,000 cycles) compared to lithium-iron-phosphate (LFP) batteries, a subset of LIBs, which can achieve 8,000–10,000 cycles.

Additionally, SIBs may require inverter modifications due to an approximate 50 per cent voltage drop compared to LIBs, posing integration challenges for EV manufacturers.

Carmakers Adopting Sodium-Ion Batteries

Several Chinese carmakers are leading the adoption of sodium-ion batteries. JAC Motors has launched an EV powered by SIBs with a 250 km range, targeting budget-conscious consumers.

Then, BYD is developing SIB-powered models, in fact, it is also constructing a 30 GWh sodium-ion battery factory to scale production.

Chery Auto, another Chinese manufacturer, has partnered with CATL to integrate SIBs with an energy density of 160 Wh/kg into its vehicles.

How They Work

Solid-state batteries (SSBs) replace the liquid electrolyte in LIBs with a solid electrolyte, such as oxides, sulphides, or polymers.

Lithium ions travel between a lithium metal anode and a cathode (often lithium-containing oxides) through the solid electrolyte during charge and discharge cycles, generating electricity.

Advantages Over Lithium-Ion

SSBs are a frontrunner in next-generation battery technology due to their potential for 50-100 per cent higher energy density (up to 400 Wh/kg) than LIBs, enabling longer EV ranges.

The solid electrolyte is non-flammable, which reduces the risk of fires or thermal runaway compared to LIBs’ volatile liquid electrolytes. SSBs also promise a longer cycle life due to improved stability, potentially outlasting conventional LIBs.

Some SSB designs eliminate cobalt and nickel, enhancing sustainability by reducing reliance on environmentally harmful mining.

Disadvantages Compared to Lithium-Ion

Despite their potential, SSBs face many hurdles. Manufacturing solid electrolytes at scale is complex and costly, delaying widespread commercialisation. Solid electrolytes often have lower ionic conductivity than liquid ones, requiring advanced materials to match LIB performance. Current production costs are high, though economies of scale could reduce them over time.

Carmakers Adopting Solid-State Batteries

Several carmakers are investing heavily in SSBs. Honda is preparing to demonstrate SSB technology with the aim of integration into future EVs.

Samsung SDI, a major battery supplier, plans to mass-produce SSBs by 2027 for automotive applications.

Toyota is also targeting SSB commercialisation by 2027-2028, though no production models currently use this tech.

How They Work

Vanadium redox flow batteries (VRFBs) are rechargeable batteries that store energy in liquid electrolytes containing vanadium ions in different oxidation states, housed in external tanks.

Unlike conventional batteries, VRFBs separate energy storage from power generation. During operation, vanadium ions in sulphuric acid electrolytes exchange electrons across a proton-exchange membrane to produce electricity.

Advantages Over Lithium-Ion

VRFBs excel in longevity, offering over 20,000 charge-discharge cycles compared to LIBs’ 1,000–2,000 cycles, making them ideal for applications requiring durability. Their aqueous electrolytes are non-flammable, enhancing safety over LIBs.

Vanadium electrolytes are reusable, improving sustainability, and the system’s modular design allows easy scaling of energy capacity, a feature LIBs lack.

Disadvantages Compared to Lithium-Ion

VRFBs are impractical for EVs due to their low energy density, resulting in bulky and heavy systems unsuitable for mobile applications. Their high initial costs and lower cycle efficiency further limit their use in EVs.

Carmakers Adopting Vanadium Redox Flow Batteries

No carmakers have implemented VRFBs in EVs due to their size, weight, and low energy density.

VRFBs are primarily used for grid-scale energy storage by companies like Invinity and Redflow. In 2013, General Electric explored VRFBs for EV applications, but no commercial vehicles have adopted this tech.

How They Work

Aluminium-air batteries use a pure aluminium anode and an air-breathing cathode. During discharge, aluminium reacts with oxygen from the air in an aqueous electrolyte, producing aluminium hydroxide and releasing electrons to generate electricity.

These batteries are typically non-rechargeable (primary batteries) but can be mechanically recharged by replacing the aluminium anode.

Advantages Over Lithium-Ion

Aluminium-air batteries have a theoretical energy density of up to 8,100 Wh/kg (far surpassing LIBs’ 150-260 Wh/kg) potentially enabling ultra-long EV ranges. Aluminium is abundant and cheaper than lithium, thereby reducing costs.

These batteries are also safer, with non-flammable electrolytes, and aluminium’s recyclability minimizes environmental impact compared to lithium and cobalt mining.

Disadvantages Compared to Lithium-Ion

The primary drawback of aluminium-air batteries is their non-rechargeable nature, requiring anode replacement, which is logistically challenging for widespread EV use. Additionally, mechanical recharging requires specialised infrastructure, which is not yet widely available.

Corrosion issues, where aluminium anodes form crystalline masses, reduce efficiency.

Carmakers Adopting Aluminium-Air Batteries

In India, Maruti Suzuki and Ashok Leyland have been testing aluminium-air batteries for quite some time now.

However, no carmakers have achieved widespread commercial adoption due to rechargeability and infrastructure challenges, making this technology a niche solution for now.

There’s no winner here, really! You see, each alternative presents unique trade-offs.

Sodium-ion batteries are cost-effective but have lower energy density, solid-state batteries offer high performance but are expensive to produce, vanadium redox flow batteries are impractical for EVs, et al.

As carmakers push these technologies forward, the future of EV batteries looks diverse, but fully replacing lithium-ion batteries could still not be a practical solution in the foreseeable future.

Also read: The Future Of EV Power? Vanadium Redox Flow Batteries Explained

Indian Racing League Round 4 Concludes With Hyman And Wohlwend Emerging Victorious For Goa Aces JA Racing

Sameer Fayaz Contractor 16 Feb, 2026, 3:41 PM IST

Limited-Run Jeep Meridian Track Edition Launched, Prices Start At ₹35.95 Lakh

Acko Drive Team 16 Feb, 2026, 1:40 PM IST

AI India Summit 2026: First Semiconductor Production Nears Rollout

Acko Drive Team 16 Feb, 2026, 1:27 PM IST

Limited Edition Ducati Formula 73 Cafe Racer Unveiled

Acko Drive Team 16 Feb, 2026, 12:53 PM IST

Nissan Gravite Launch Tomorrow: Here's what to expect

Acko Drive Team 16 Feb, 2026, 11:32 AM IST

Looking for a new car?

We promise the best car deals and earliest delivery!