Key Components and Functions of a Car Pressure Plate

Before looking at how the pressure plate works, it helps to understand the major parts involved and the purpose each one serves.

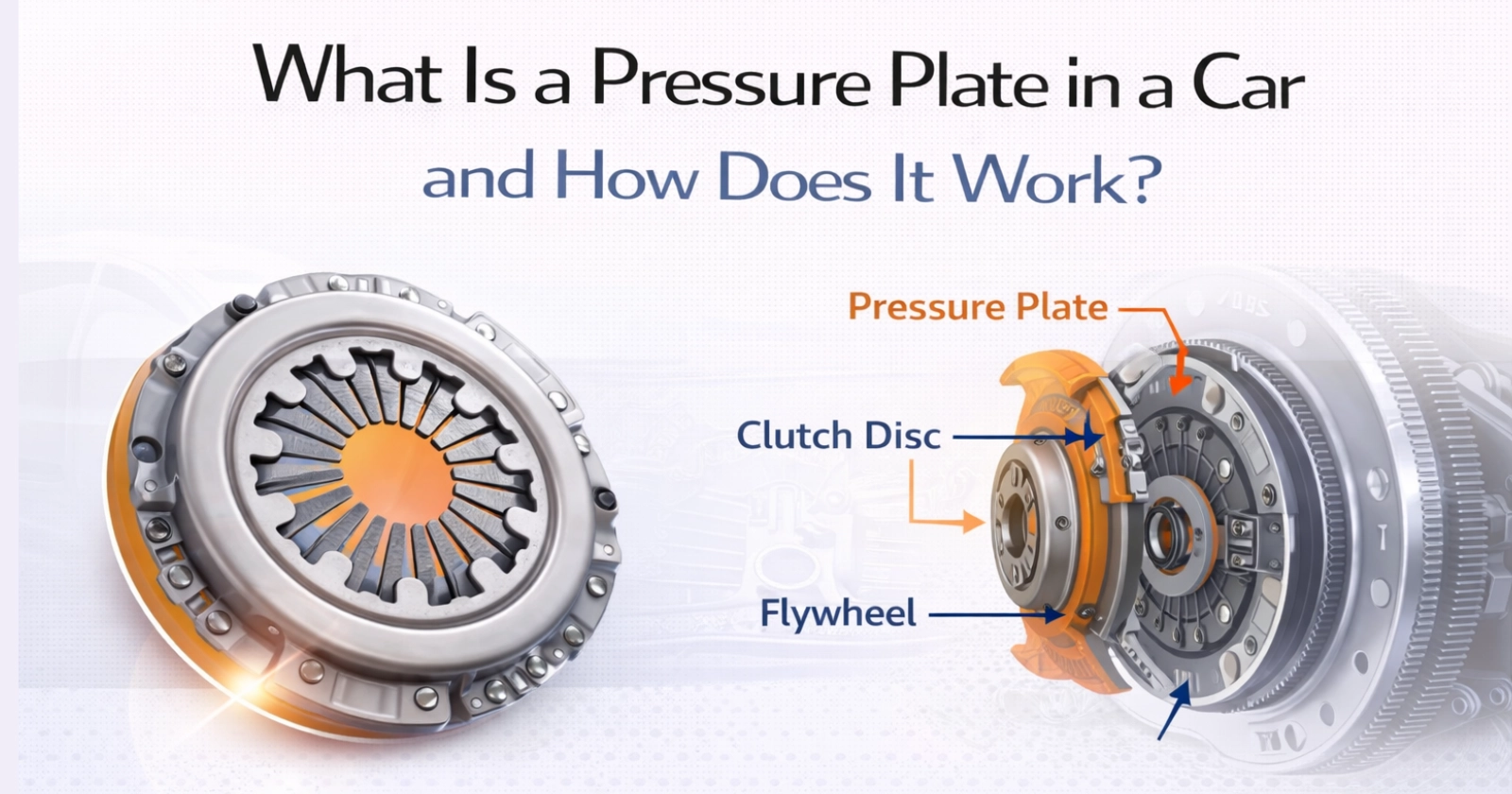

Clutch Disc and Flywheel Interaction

It is positioned on the flywheel and presses the clutch disc hard against it. If the clutch disc is held tightly between the plate and the flywheel, then engine power flows directly to the transmission.

That contact between the metal and the friction material is what allows the car to move forward. When that contact breaks, the engine and gearbox become disconnected, which enables the driver to change gears.

Diaphragm Spring vs. Coil Spring Designs

The pressure needed for clamping the clutch disc comes from springs that are integrated in the pressure plate assembly. There are two major designs:

- Diaphragm spring: A flat, usually circular spring with fingers in the centre provides constant pressure, requires less pedal effort, and hence finds application in almost all modern cars.

- Coil spring: A number of small coil springs around the plate are used. It usually finds its application in heavier or older vehicles.

The type of spring affects the clutch pedal feel, the smoothness of engagement, and durability.

How the Pressure Plate Applies Force

The springs inside it push against the clutch disc onto the clamping surface of the pressure plate. Every time the clutch pedal is depressed, it acts on the release bearing, which relieves pressure from the clutch disc as the diaphragm or coil springs push inwards.

Put simply, it is the pressure plate's job to push down, thereby engaging the clutch, or pull away, which in turn disengages the clutch.

How a Pressure Plate Works

Even though the mechanism is mechanical in nature, the process is quite straightforward once broken down into steps.

Engaged Position: Transmission of Engine Torque to the Transmission

The pressure plate springs return to their natural position and clamp the clutch disc firmly against the flywheel as soon as the driver releases the clutch pedal.

In this position:

- The engine and transmission rotate together

- Power is smoothly transmitted to the wheels.

- The car accelerates without slipping.

- This is the state in which the clutch stays during normal driving.

Disengaged Position: Allowing Gear Changes Without Grinding

When the driver presses the clutch pedal, the release bearing moves towards the centre of the pressure plate and pushes the spring fingers inwards.

This mechanism is responsible for:

- Less pressure between the clutch discs.

- Separating the disc from the flywheel.

- Disengages the torque connection from the gearbox.

This results in smooth gear shifting and prevents damage to the transmission mechanism as the disc is disengaged.

The role of the release bearing and clutch pedal in operation

The pressure plate and the driver’s foot are connected through a firm mechanism called the release bearings. When the clutch is engaged, the pedal moves forward and releases the fork, which in turn, releases the bearings. The bearing presses on the diaphragm or coil springs. The pressure upon the clutch disc is released. This chain of action enables smooth changes between gears and prevents excessive wear on the gearbox.

Types of Pressure Plates

There are different clutches and pressure plates designed for different vehicles, depending on the power of the engine, weight, and usage.

Diaphragm Spring Pressure Plates-most common in modern cars

These are widely used because of their:

- Lower pedal effort

- Smooth engagement

- Good clamping force

- Compact design

This type is in use by most modern hatchbacks, sedans, and even SUVs.

Coil Spring Pressure Plates (Older Models)

Found mainly in older models or heavy-duty machinery, coil spring plates offer:

- Strong clamping force

- Simple, rugged construction

These do require more pedal effort and may not be quite as smooth in engagement.

Multi-Plate vs. Single-Plate Systems

Most everyday cars have single-plate clutches, consisting of one clutch disc and one pressure plate.

Multi-plate systems use two or more discs:

- Found in high-performance cars and some motorcycles

- Handle more torque in a compact size

- Engage more quickly

- These systems aren't for day-to-day driving; they're for high-power usage.

Warning signs of a failing Pressure Plate

A faulty pressure plate generally will affect drivability and clutch performance overall. Early signs can be detected to avoid breakdowns that could cause damage to your transmission.

Slipping Clutch Under Acceleration

If the engine revs go up but the car does not accelerate proportionately, that could well mean that the pressure plate does not clamp the clutch disc with sufficient force.

Difficulty Shifting Gears

A worn-out pressure plate fails to release the clutch disc, making the gears grind or resisting the movement of the gear lever.

Vibration or Chatter When Engaging the Clutch

It could be due to uneven pressure on the disc, which causes the shuddering or vibration when starting from a standstill.

Smell of burning due to the overheating of the Clutch

Slipping creates excess heat that can create a very distinctive smell of burning when driving uphill or during heavy traffic flow.

Unusual Noises When the Clutch Pedal Is Pressed

Squeaking, grinding, or rattling may be heard due to worn spring fingers, a damaged release bearing, or internal pressure plate wear.

Tips to Extend the Life of a Pressure Plate

Proper driving habits combined with timely maintenance will go a long way in extending the life not only of the pressure plate but of the whole clutch system.

Avoid Riding the Clutch Pedal

This partial release is done where the pedal is kept pressed a little, and premature wear and overheating result.

Smooth engagement of the clutch when stopping or starting

Releasing the clutch abruptly can put unwanted stress on the pressure plates and increase friction in the assembly.

Inspecting and timely maintenance of the clutch system

Timely inspection of the clutch component and assembly parts can help identify several issues, such as hydraulic leaks, worn-out springs or misaligned components that may lead to clutch failure.

Replace Clutch Components in Matched Sets

Whenever replacing a pressure plate, it is also best to replace the clutch disc and release bearing for even wear and improved long-term performance.

Proper Break-In for a New Clutch and Pressure Plate

Most of the new clutch kits have a break-in time of about 500–800 km. Gentle driving during this time ensures the friction surfaces bed in correctly.

Bottom Line

The most crucial component responsible for smooth gear changes and efficient power transfer is the pressure plate. Manual transmission cars function primarily on an optimum pressure plate, as it solely controls the driving comfort and transmission mechanism health.

Being aware of the mechanism and early signs of wear will help one have better control over their car, ensuring that costly repairs are avoided. Clutch systems are complex and fragile if not maintained properly. They can last a lifetime if proper care is shown towards the assembly, but can also burn down within 2-3 months if subjected to rough use.

Frequently Asked Questions