Chinese scientists create a flexible ‘armour’ layer for solid-state batteries, enabling 7,000+ hours at -30°C and 4,500 hours under heavy load.

Share Post

Chinese scientists create a flexible ‘armour’ layer for solid-state batteries, enabling 7,000+ hours at -30°C and 4,500 hours under heavy load.

Researchers from Tsinghua University’s Shenzhen International Graduate School and Tianjin University have pioneered a flexible protective layer for solid-state batteries, enhancing their durability in freezing temperatures and high-power scenarios.

The breakthrough, detailed in a research paper published on October 29, could accelerate the adoption of these next-gen EV power sources.

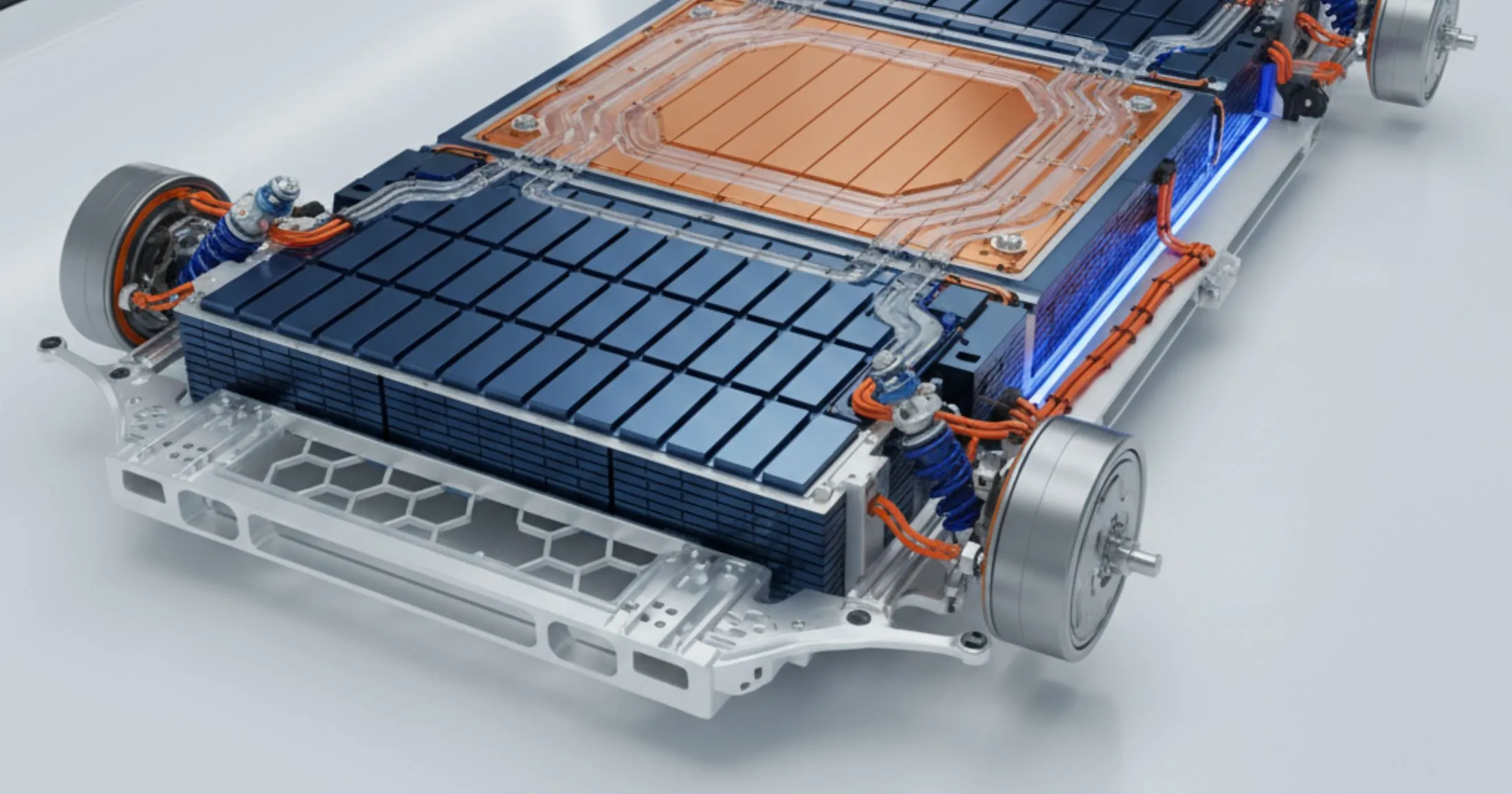

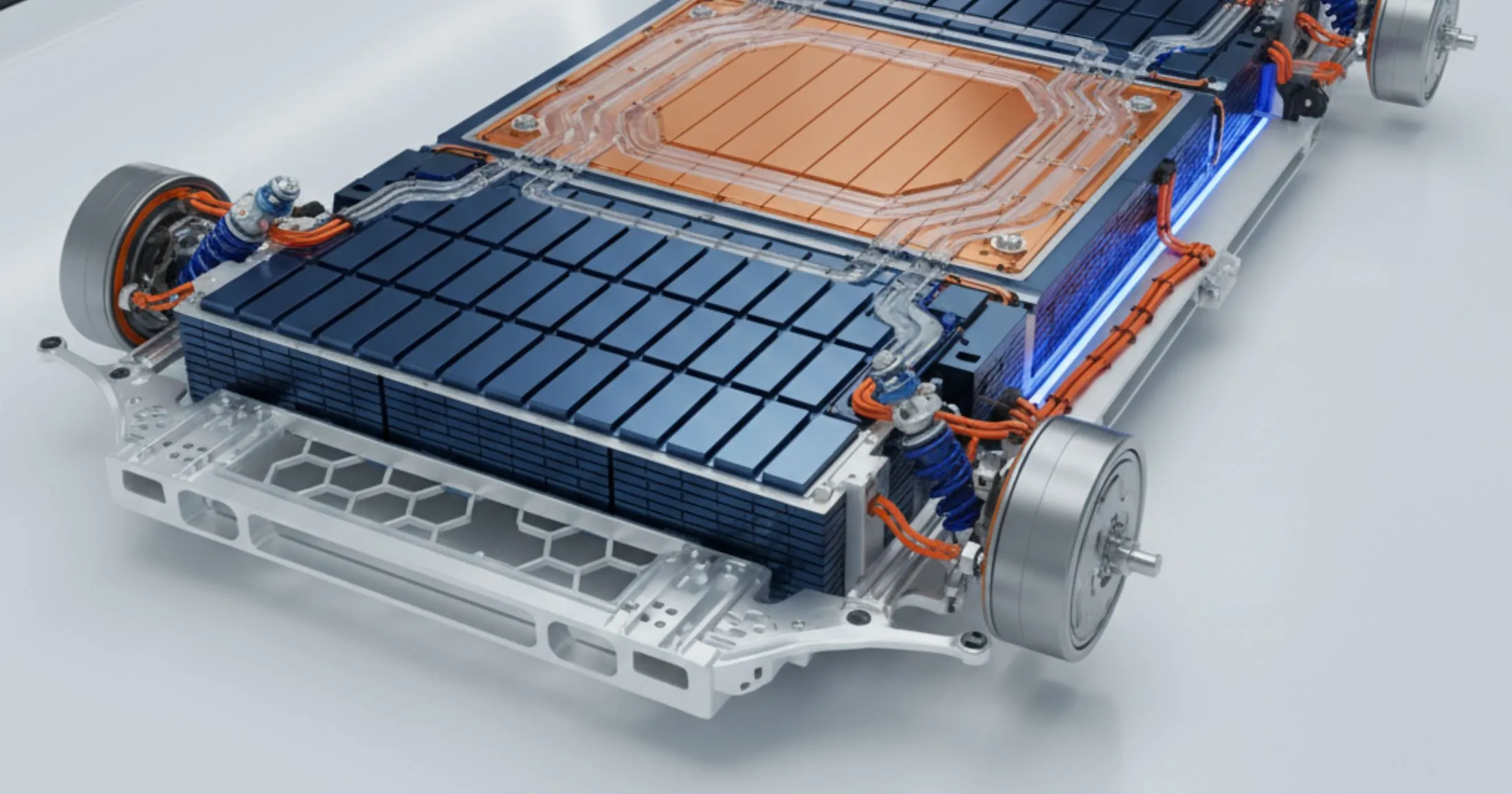

Solid-state batteries promise higher energy density and safety over traditional liquid lithium-ion cells, avoiding risks like overheating or fires. However, their brittle solid electrolyte interphase (SEI) often cracks during rapid charging or sub-zero conditions, leading to uneven lithium plating and reduced lifespan.

The team’s innovation replaces this rigid barrier with a ductile, bendable version using silver-based materials. This “armour” layer flexes under stress while permitting smooth lithium-ion flow, preventing fractures and maintaining structural integrity.

The design features a gradual transition from soft to stiff materials, minimising internal pressures during charge-discharge cycles. This layered approach ensures even lithium distribution, curbing dendrite formation that degrades performance.

In lab trials, batteries with the new coating endured over 4,500 hours of intensive operation and remained stable for more than 7,000 hours at -30°C, conditions that typically doom conventional solid-state prototypes. The results underscore the layer’s potential for reliable real-world use in EVs across harsh climates.

Led by Professors Feiyu Kang and Yanbing He from Tsinghua, alongside Quanhong Yang from Tianjin, the project received backing from China’s National Natural Science Foundation, National Key R&D Programme, and Shenzhen’s innovation fund.

While mass production hurdles persist, this advance paves the way for solid-state batteries in vehicles by 2027, aligning with timelines from firms like CATL for 500 Wh/kg cells.

Also read: Wipro, IISc Make India's Indigenous Driverless Car WIRIN in Bengaluru

Automakers Review Shipments to Gulf as Geopolitical Risks Rise

Team Ackodrive 7 Mar, 2026, 11:32 AM IST

Hyundai Offers Super Delight March Discounts Across Lineup

Acko Drive Team 7 Mar, 2026, 9:18 AM IST

New Honda Insight EV Debuts in Japan with 501 km Range

Acko Drive Team 7 Mar, 2026, 8:02 AM IST

Mahindra Teases XUV 7XO Women’s Edition

Acko Drive Team 7 Mar, 2026, 6:43 AM IST

Renault's RGMP Platform Set For 5-Star NCAP Safety?

Ameya Naik 7 Mar, 2026, 5:36 AM IST

Looking for a new car?

We promise the best car deals and earliest delivery!